What Is The Advantage Of Using A Helicoil Vs Timesert When Repairing A Threaded Hole?

What Thread Repair Kit or Insert is Best for Your Job?

And What is the Forcefulness of Your Called Thread Repair or Insert.

You've found your Australian importer of thread repair inserts & tools - Time-Sert, Helicoil compatible wire type, Keensert, E-Z Lok, ensat, tapper and self tapping thread inserts and alternatives used for thread repair or in OEM manufacture. Afterward about 40 years experience supplying thread inserts and tooling we'd similar to say there isn't just one reply to the questions above considering every job is different. Yous'll find below what nosotros believe are the 4 all-time choices in thread repair inserts and how they work. At the bottom of this page yous'll also find details of other less common and more specialised types of thread inserts. The choice is yours once y'all know how thread repairs and inserts work. Sparkplug, fuel injection hole and sump drain thread repair in aluminium is a common trouble and you'll detect the remedy at Cross Tools in our broad range of stock of the diverse types of thread inserts from very small to large sizes. If you've got a thread repair problem why non phone 1 800 025 500 [FreeCall] and have a chat? You can expect your order express delivered straight to you Commonwealth of australia-wide to most places in 24 hrs or less.

How strong will your thread repair or OEM assembly be?

Thin Wall Inserts Like Fourth dimension-Sert & NuCoil

Any task repaired with any thread insert at all will exist stronger than the original pigsty tapped direct into the parent metallic. This is because when you tap an oversize thread to accept the insert, you lot are increasing the bore. This automatically ways you lot have more surface surface area in contact with the parent and consequently more "grip". For instance in aluminium, or cast iron with a Fourth dimension-Sert you probably gain 10-15% extra load bearing capacity and with a wire thread helical coil type insert maybe twenty-xxx%. In steel, of course, a Time-Sert is the aforementioned cloth and a helical curlicue type insert is usually stainless steel. This means that you become very piddling actress forcefulness from a Time-Sert but from a helical coil type insert y'all go mayhap 10-20% actress force due to improve loading and the extra tensile strength of stainless. The pictures in the right hand column show why.

Thicker Walled Inserts Like

Big Sert and Loc-in-Sert

In aluminium or bandage atomic number 26, with large bore solid bush type inserts like Big-Serts or Loc-in-Serts, you automatically increase load bearing chapters by a substantial amount because you are making a considerably larger thread in the parent cloth. In steel, of class y'all don't gain much in strength merely y'all do proceeds the benefit that if the insert strips its internal thread, yous can just screw it out and supercede information technology generally without damage to the parent item.

The Forcefulness Reward of NuCoil Inserts

Hellically coiled wire thread inserts brand the strongest thread connectedness currently known to engineers. They likewise increment the useful life of the

parent office because they salvage stress on the

threaded assembly. You'll see why from the diagrams below. The grey shading represents stress effectually the thread.

Picture at left represents a bolt straight into it'south parent material without a thread insert

Notice that the grayness stressed expanse is mainly effectually the top 3 threads. In fact if you measured it you would find about l% of the load was on the starting time thread!

This picture show represents a bolted connection with a NuCoil insert

See how the grey stressed area is nicely distributed. Stress is far more than fifty-fifty over well-nigh 6 threads so the connexion is far less likely to fail and the parent part has a longer fatigue life.

Keensert Type Key Locking Threaded Inserts - Permanent & Vibration Proof

Keyed Insert (pictured at left)

This insert locks in place past using "keys" which show in the motion-picture show protruding above the insert. Once the insert is screwed into its parent hole, the keys are knocked down into the parent and provide a positive mechanical lock. For some applications this is desirable but the keys cause slight impairment to the parent thread and in some applications can atomic number 82 to fluid or gas leakage e.chiliad. in sparkplug holes. We generally prefer Loc-in-Serts featured beneath as a improve option. The pre-applied Loctite on Loc-in-Serts does not damage the pigsty and, after all, Loctite is considered suitable for nearly critical applications these days.

Loc-in-Sert

Thick wall insert for repair where thinwall inserts accept failed. Also used in dies for plastic moulding and metal stamping.

Loc-in-Serts are thick wall threaded bushes and are good for a repair if a helical coil or Time-Sert insert has failed. They are also used in plastic moulding and metal stamping dies and machinery. The reward of Loc-in Serts is that they use standard size taps and have ordinary threads on the outside. Then special tools are not needed and setup cost is low. When used as hold down threads in plastic and stamping dies they go a replaceable threaded bush-league i.e. when the thread wears they are relatively piece of cake to remove and exercise not harm the parent thread. You merely screw a new Loc-in-sert in and you accept a make new thread! Pre-applied Loctite on the outside of the insert self activates as you lot screw a Loc-in-Sert in and automatically stops information technology coming out.

Familiar with LocinSerts?

Click here for product list

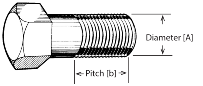

How to measure a thread . . .

What do you lot demand to know for starters?

To illustrate how to measure a thread let's employ the virtually familiar member of the screw thread family - a bolt. If y'all need to depict any thread, including thread repair inserts, you need to know accurately the "pitch" and the "diameter". You should e'er attempt to have the male person thread available to measure e.g. a bolt or stud rather than try to mensurate an internal thread. Measuring internal threads accurately is far more difficult and open to errors.

The elements needed to measure a thread are illustrated on the bolt pictured below:

Diameter [A]: This needs to exist measured with a precision caliper or micrometer to be certain what thread yous have.

An example of how a METRIC THREAD is described is: either 10mm x1.v or M10x1.5 (both terms mean the same thread) which is 10mm bore and ane.5mm thread "Pitch" every bit pictured [b] in a higher place.

This "pitch" 1.5mm is the altitude betwixt

each loma or peak on the thread as pictured

IMPERIAL or "INCH" threads are described differently for example: 3/viii"-16 UNC or 3/8"-xvi BSW

3/8" is the bore and xvi is the "Pitch" [b] (as per movie in a higher place). Merely in the "inch" organisation pitch is said to be and so many threads to every inch of thread length. (In the instance above this is 16 threads per inch). "Threads per inch" is as well abbreviated to its initials " tpi" for short. Then, the "inch" system describes pitch as the number of threads over a 1 inch length and non equally the distance between the peaks of a thread similar the metric organization.

An INCH thread will usually be followed by some initials like the example above. These initials describe the type and the engineering standard for the thread. For the above case UNC stands for "Unified National Coarse" and BSW stands for "British Standard Whitworth". To an engineer, this classifies and defines the type of thread.

Self Tapping Thread Inserts

![]()

Self Tapping Inserts (ii pictures at left)

These inserts cut their ain thread using either a precipitous sided slot or pigsty. Both types are pictured. The external threads are oft shallower than a tapped hole and we consider them not the best insert to use for repairs. One reason is it's easier to misalign this type of insert. Their main application is in OEM either in softer metals or plastic where mass tooling tin can be fix to manufacture.

Fast commitment Australia-wide directly

from your importer & trade supplier

Phone FreeCall 1800 025 500

PO Box 55, KOTARA NSW Australia 2289 PHONE 1 800 025 500 ABN 44564673401

© 2022 Cross Tools Co

Back

to

Top

Source: https://www.crosstools.com.au/thread-repair---which-type-is-best-for-you.html

Posted by: mckissackfrien1940.blogspot.com

0 Response to "What Is The Advantage Of Using A Helicoil Vs Timesert When Repairing A Threaded Hole?"

Post a Comment